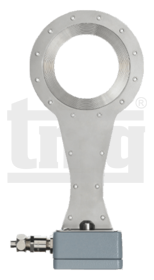

flange seal sensor TB/UB30

Flange gasket with integrated temperature measuring points

![[Translate to Englisch:] bis PN400 Nenndruck](/fileadmin/_processed_/f/7/csm_flanschdichtungsfuehler_nenndruck_f1289280a5.png)

![[Translate to Englisch:] bis 250m/s Strömungsgeschwindigkeit](/fileadmin/_processed_/5/d/csm_flanschdichtungsfuehler_stroemungsgeschwindigkeit_0bf873eda0.png)

![[Translate to Englisch:] bis 600°C Betriebstemperatur](/fileadmin/_processed_/e/c/csm_flanschdichtungsfuehler_betriebstemperatur_4dacc68dc1.png)

- Installation & retrofitting in flanged joints without high assembly, testing and acceptance costs

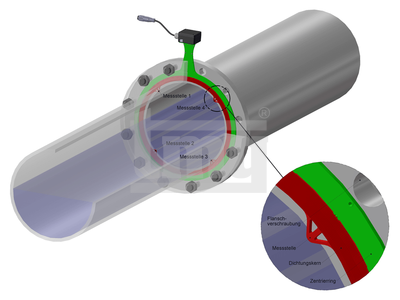

- Average or single value measurements on the entire 360° circumference

- No turbulence or influence on the pipe flow

- Robust despite extreme operating conditions

- Use in potentially explosive atmospheres

Type TB/UB30 is a static seal for flange connections with integrated temperature measuring points for very accurate recording of the temperature of the flow medium in pipelines.

The measuring signal can be integrated and processed in all process control systems and used to control and regulate processes. Average values are recorded or specific individual temperature values are recorded over the 360° circumference of the inner pipe surface.

Performance features:

- Measurement signal:

- Thermoelectric voltage according to EN 60584

- HART protocol, Profibus, 4...20mA - Thermocouples single, indirect

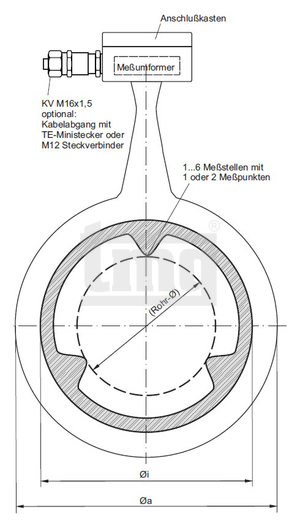

- Number of redundant measuring points: 1...8

- Single value acquisition, average value acquisition

- Accuracy: Class 1 according to DIN EN 60584-1

- Operating temperature: -40...+600°C

- Dimensions DN 25... DN400

- Flow velocity up to 250m/s

- Operating pressure up to PN400

- Including mathematical strength and tightness verification for the flange connection according to DIN EN 1591-1

Advantages of using the TB/UB 30 flange seal sensor

- Insensitive to breakage and abrasion, especially with media containing solids

- For use with very high flow velocities

- Pressure-proof

- Diagnosis of filling level ratios in the pipe possible

- Easy installation (opening and closing of a flange connection)

- Cost-effective compared to the high-risk work of subsequently welding in thermometer protection sleeves.

Option: Ex-protection

II 1G Ex ia IIC T6…T1 Ga

II 1D Ex ia IIIC T135°C Da

II 2G Ex ib IIC T6…T1 Gb

II 2D Ex ib IIIC T135°C Db

In the UB30 version, the flange seal sensors can be used in potentially explosive areas with gas or dust atmospheres.

The gasket can be installed on flange connections with sealing surface forms A and B according to DIN EN 1092 as well as form RF according to DIN EN 1759 and ASME B16.6 as well as B16.47.The dimensions of the gasket core do not correspond to the common standards, but are specially optimised for improved temperature absorption.

Total seal height before installation and centring diameter correspond to the standardised seals of the standards DIN EN 1514 and DIN EN 12560. Also available as RTJ seal according to DIN EN 12560-5 or ASME B16.20.

All common CrNi steels as well as Ni-based materials can be used as carrier materials. Covers and centring plates are made of CrNi steel as standard, but can also be made of other materials on customer request.

On the connection side, the thermoelectric seals can be equipped with terminal boxes, connectors and/or transmitters.

The following information is always required for ordering and interpretation:

- Flange standard or apparatus drawing

- Nominal width

- Nominal pressure stage

- Pipe wall thickness of the connected pipe

- Insulation thickness

- Materials of the flanges used

- Materials of the bolts used

- Design and operating parameters (pressure & temperature)

- Temperature measuring range (incl. transmitter if ordered)

- Medium transported (for possible correction factors)